The dried milk powder was dispatched in these barrels made of plywood and known as Venestas (from the name of the firm that made them).

The dried milk powder was dispatched in these barrels made of plywood and known as Venestas (from the name of the firm that made them).

Picture of the dried milk powder barrels.

Bill Northam with an early milk churn.

Bill Northam with an early milk churn that could hold 17 gallons of milk (75 litres) and would weigh 210 lbs (90kgs) when full.

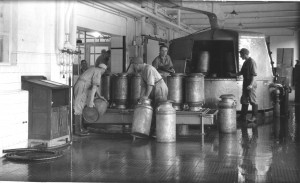

The first sterilisation plant for the milk churns.

The first plant for sterilising milk churns before their re-use. These 10 gallon churns were emptied and upended on the receiving tank, they were then placed inside the steam steriliser where they revolved in a clockwise direction. The man on the right is removing the clean churn ready for re-use. The churn lids went through the same process.

The first plant for sterilising milk churns before their re-use. These 10 gallon churns were emptied and upended on the receiving tank, they were then placed inside the steam steriliser where they revolved in a clockwise direction. The man on the right is removing the clean churn ready for re-use. The churn lids went through the same process.

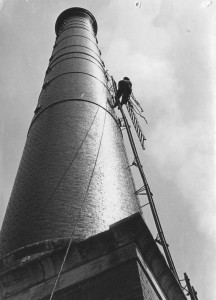

Steeplejack inspecting the old chimney.

A steeplejack at work during a regular inspection of the old chimney.

A steeplejack at work during a regular inspection of the old chimney.

The factory in its coal burning days.

The factory in its coal burning days, a Renwick Wilton coal truck can be seen being unloaded. The cows in the picture could almost deliver their milk directly to the factory.

The factory in its coal burning days, a Renwick Wilton coal truck can be seen being unloaded. The cows in the picture could almost deliver their milk directly to the factory.

Two of the older milk factory lorries.

View of the milk reception bay with two older lorries.

View of the milk reception bay with two older lorries.

Mr. W. Miller at the controls of the milk powder plant.

Mr. W. Miller at the controls of the milk powder plant.

The christmas party of the milk factory in 1940.

The social side of life was not neglected, this is a Christmas party for the children of the employees in the old factory hall c. 1940.

The social side of life was not neglected, this is a Christmas party for the children of the employees in the old factory hall c. 1940.

Mr Mutter with 5 milk tankers ready for London.

Mr. L. Mutter with one days supply of milk in 5 tankers ready to be taken to London.

Mr. L. Mutter with one days supply of milk in 5 tankers ready to be taken to London.